Test facilities and characterisation

The aim of the power electronics team’s test resources is to test and characterise the various components of power converters. Consequently, there are several test benches for the characterisation of the active and passive component aspects, electromagnetic compatibility (EMC) and components for the storage of electrical energy, as well as several simulation software tools.

1. Characterisation means for active & passive components

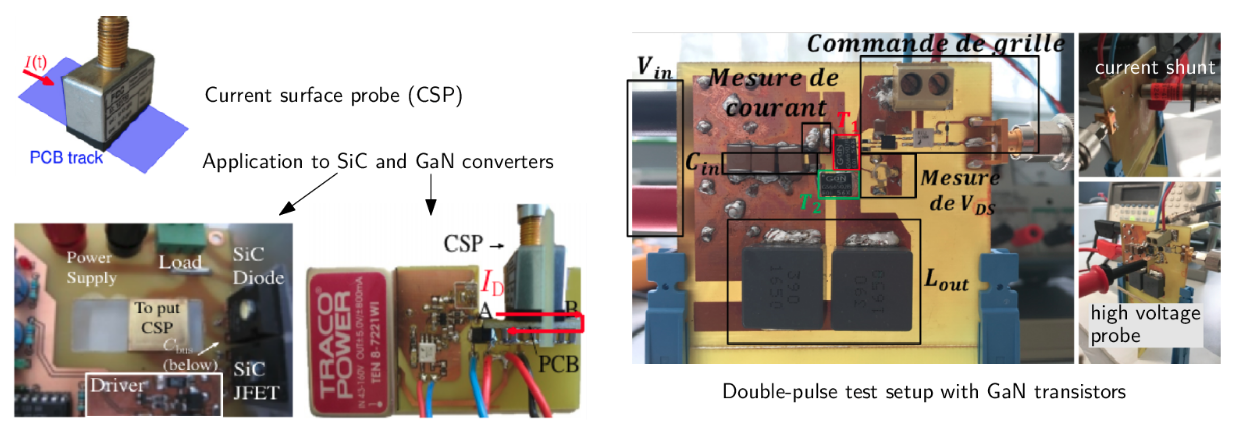

As part of the research activities on HF converters, the voltage and current can be measured by active probes (bandwidths of at least 100MHz for ratings of at least 1000V and 30A, respectively) as well as passive probes (4kV 400MHz probe, 1GHz shunts, etc.) by viewing the signals on oscilloscopes. These probes are particularly suitable for measuring the rapid variations in voltages and currents in switching cells that contain semiconductor components using materials with a wide band gap (SiC, GaN). In particular, the team has a surface current probe which is used to conduct non-intrusive, high-bandwidth measurements of switched current on the nanosecond scale, with low insertion impedance. A 2GHz oscilloscope will cover the entire bandwidth of the most sophisticated equipment.

GaN & SiC COMPONENT CHARACTERISATION

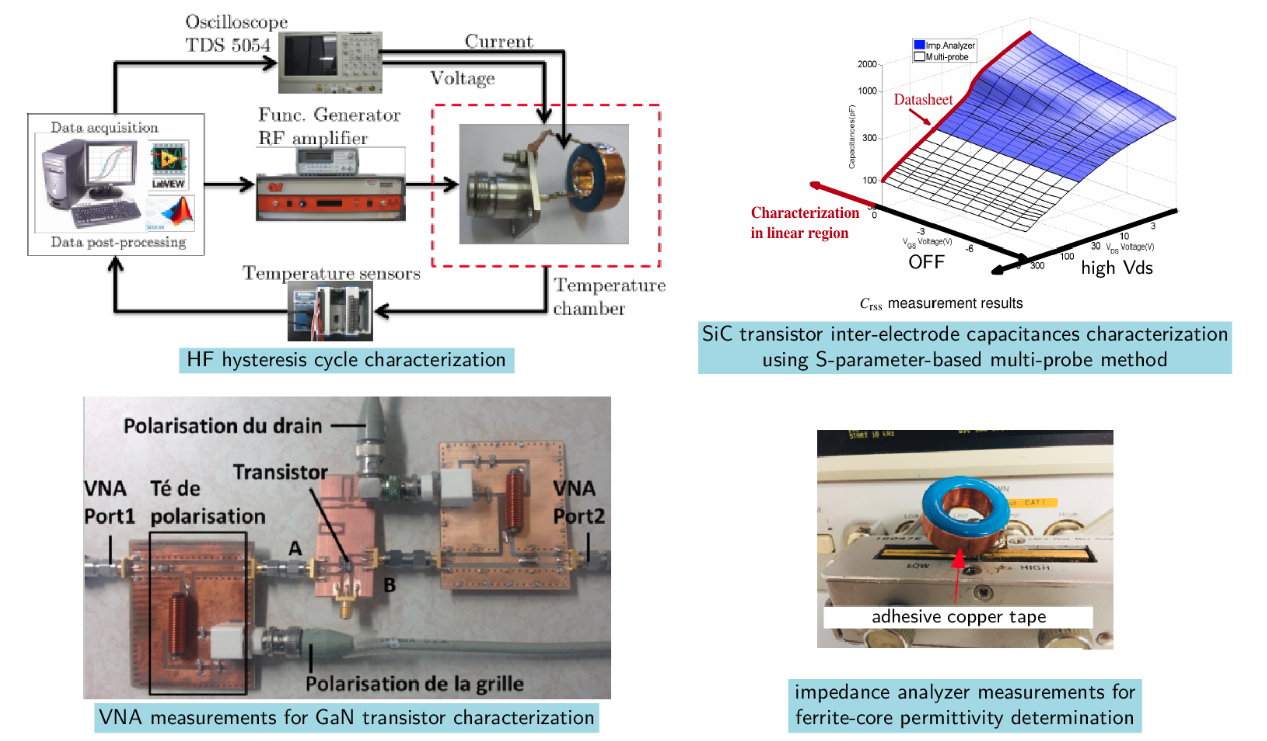

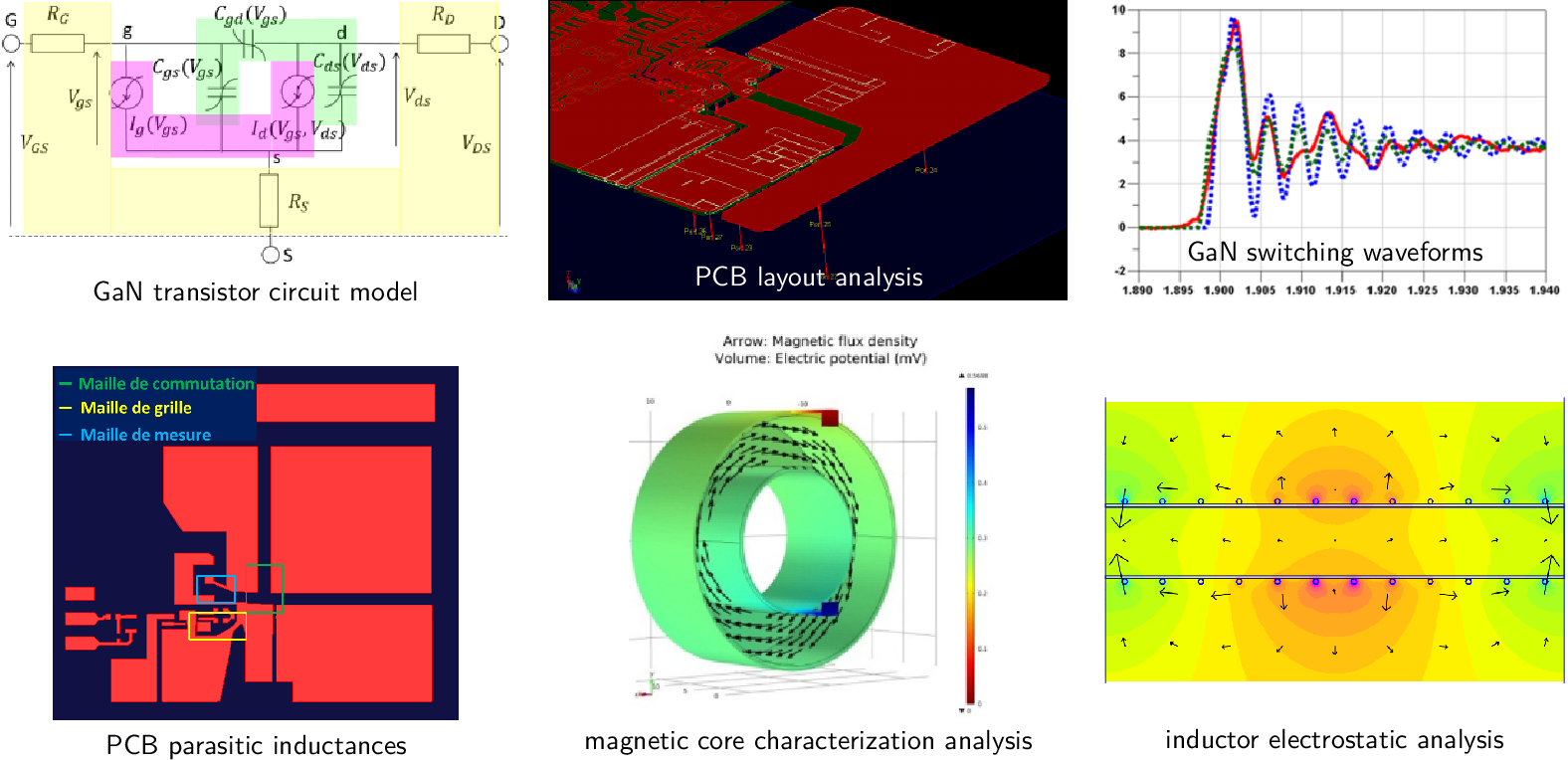

The team has several programmable power supplies with a power rating of 10kW, specific loads and various measuring resources dedicated to the characterisation of the materials and components used in its various activities: impedance analyser (up to 110MHz), precision micro-ohmmeter, vector network analyser (VNA, from 9kHz to 4.5GHz), HF power amplifier, current injection and reception clamps, computer-based data acquisition and instrument control resources. In particular, these tools are used for the magnetic and dielectric characterisation of magnetic materials according to the frequency and thermal and polarisation stresses, as well as for the static and dynamic characterisation of power semiconductor components. This is to establish models that faithfully replicate the behaviour of the devices studied. In terms of electronic prototyping, the team has printed circuit engraving equipment as well as equipment for producing multilayer circuits and mounting SMD components.

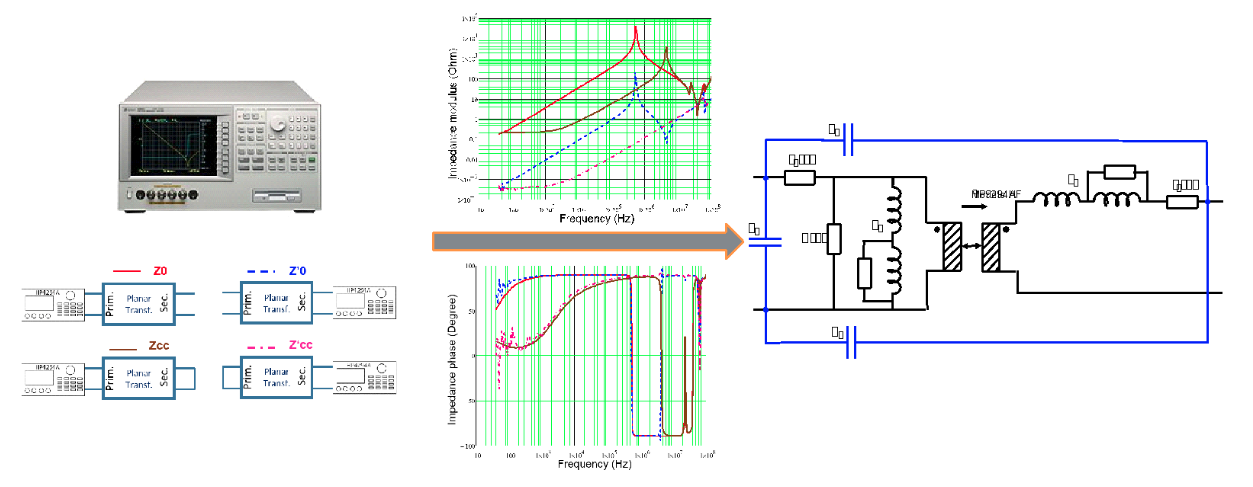

EXAMPLES OF MEANS USED TO CHARACTERISE ACTIVE & PASSIVE COMPONENTS

These experimental means are associated with characterisation methods developed within the EP team, whether it is for active or passive components.

SMALL SIGNAL CHARACTERISATION OF A PLANAR TRANSFORMER USING AN HP4294A IMPEDANCE ANALYSER

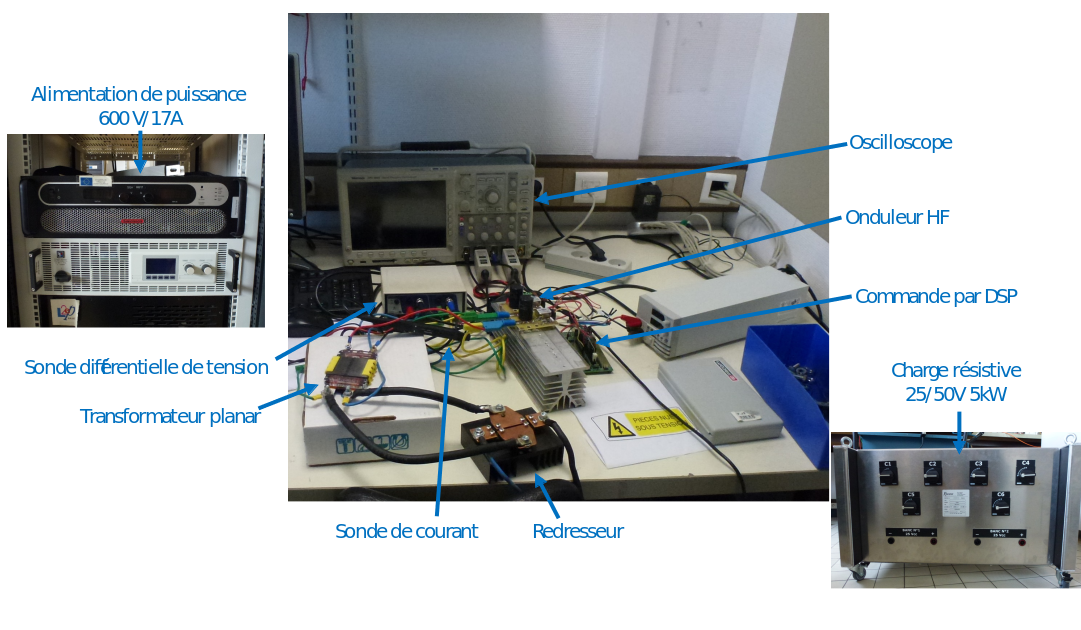

Specific characterisation test benches can also be developed for component power tests. There are thermal cameras, which can be used to measure the increase in temperature in the components.

PLANAR TRANSFORMER POWER CHARACTERISATION TEST BENCH (5kW)

2. EMC tests

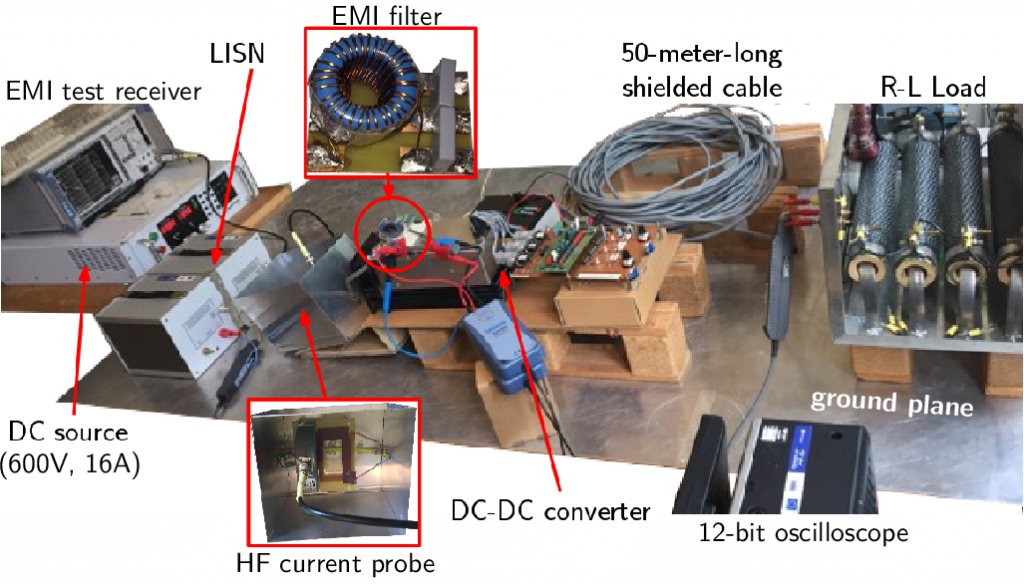

The EMC-related experimental activities have areas equipped with layout plans, several line impedance stabiliser networks (LISN) adapted to various standards, an EMC measurement receiver and various other pieces of equipment used to study the propagation of conducted interference at high frequency (HF) in a power conversion chain. Consequently, the team has a spectrum analyser, various HF current transformers (bandwidths up to several hundred megahertz) and a high-resolution oscilloscope (12 bits) that can complete frequency measurements using time analyses.

EMC CHARACTERISATION TEST BENCH

3. Characterisation and battery and supercapacitor cycling bench

The power electronics team has two characterisation and cycling test benches of components for storing electrical energy (batteries and supercapacitors). The first, which is for testing packs, can go up to 60V and 400A. It is equipped with 12 temperature sensors and can measure up to 28 voltages of elements in series. It is therefore unique in that it can test a pack as a whole, while also looking in detail at the elements of this module.

Module test bench & test bench with four measurement channels

The second test bench aims to characterise the energy and electrical behaviour of elements for high current applications (500 Amps). The special feature of this test bench is that it is modular, i.e. it can be adapted to a large number of storage systems by carrying out the minimum of software or hardware modifications.

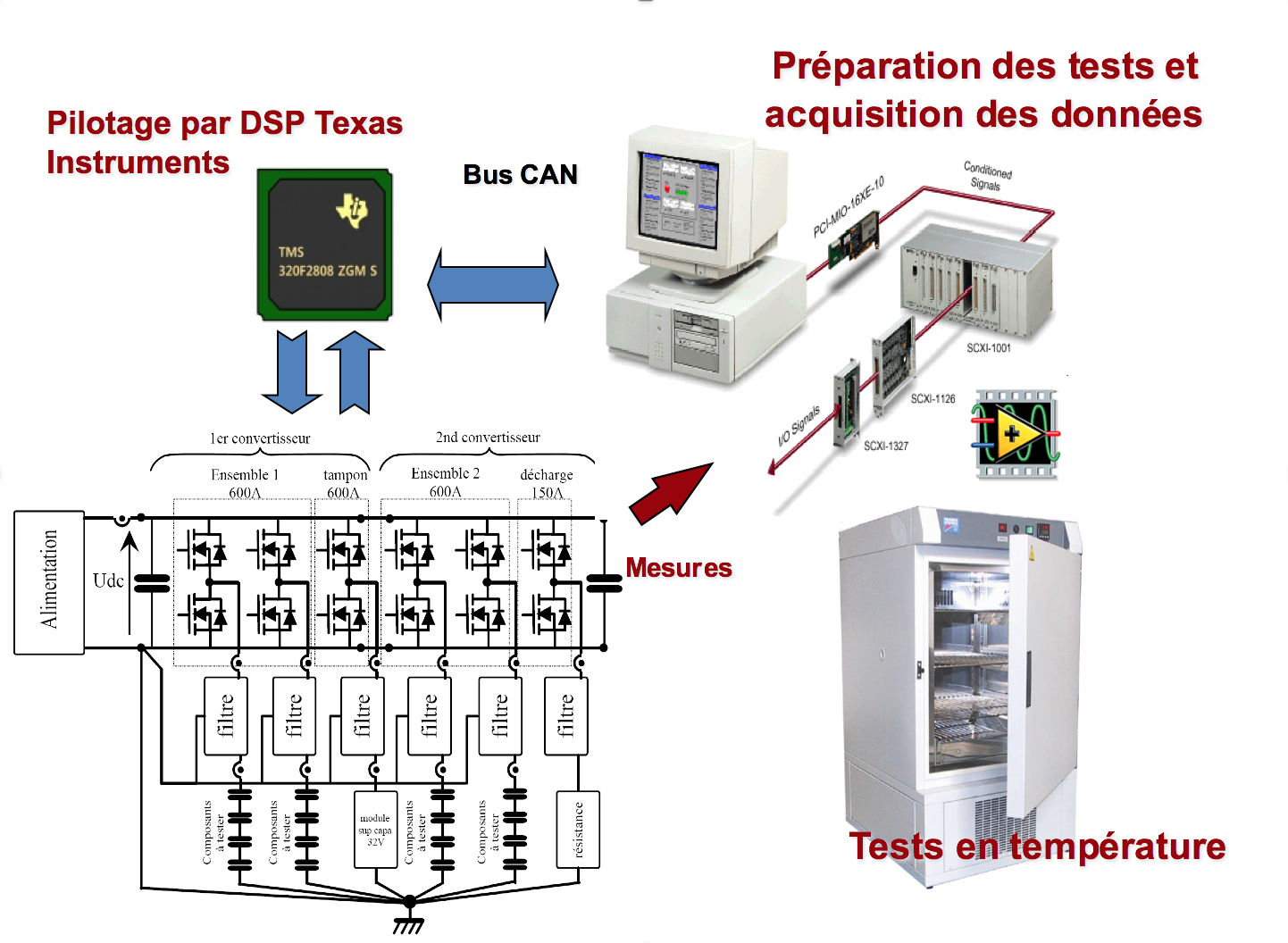

The test bench is made up of four cycling channels and measures with voltage and current ratings of 20V and 600A. It can therefore be used to increase the number of tests under different conditions. The channels operate in pairs with opposing operating cycles, the objective being to limit the peaks in the power to be delivered when a large number of channels are used simultaneously.

Flow chart of the test bench with four measurement channels

These two complementary test resources go hand in hand with methods used to characterise Li-Ion supercapacitors and accumulators developed by the team in partnership with ESTACA (Laval).

4. Simulation tools

The experimental characterisations are used to model and numerically simulate the devices studied under different computer environments dedicated to the study of circuits or the calculation of fields (PSpice, PLECS, PSIM, LTspice, ADS, Comsol, InCa3D, FEMM, ANSYS) as well as to process data (MATLAB, Python). A workstation has enough computing power with high availability for long calculations.

NUMERICAL SIMULATION TOOLS