Scientific developments

Power Electronics is central to the current energy concerns, particularly within the context of « Energy and Sustainable Development » initiatives. The EP team focuses its research efforts on the critical points associated with Power Electronics via issues with innovative industrial energy applications. Its projects are focused on its know-how in structures, close control, components and the reduction of electromagnetic interference generated by the converters. This requires a broad range of skills in Electrical Engineering (active components, electromagnetic compatibility, filters, real time control, etc.) in order to be able to adapt these converters to their environment. The objective is to make the most effective use of the components to ensure the best compromise between « simplicity – energy efficiency and energy quality ».

Currently, the team focuses its research work primarily on the increase in frequency of conversion structures for low and medium power applications, and collaborates with the Networks team on the increase in voltage of converters connected to High Voltage networks (HVDC) by using converters of the Modular Multilevel Converter (MMC) family.

In order to increase the frequency of the converters, all the structural elements must be extensively modelled. In this way, the characterisation and modelling of the components (active, passive, connections, etc.) are the basic building blocks of the design of HF converters. The same applies to the modelling and selection of their local control. As a result, the performance of these devices can be used to greatest effect, both in terms of energy conversion and their EMC behaviour.

1. Modelling, characterisation and design of the magnetic components for

the converters:

Power planar inductors and transformers

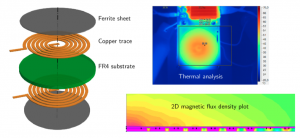

In order to improve the power density of converters, it is of utmost importance to reduce the volume of the passive elements, especially regarding the smoothing coils which must be adapted to the increase in frequency of the converters (large gap components). In this way, the team is involved in creating and optimising relatively compact coils made on printed circuits with thin magnetic materials, while devoting special attention to the thermal effects as well as controlling the electrostatic phenomena which can restrict the high frequency range at which these components can be used.

These solutions are currently intended for low power large gap converters.

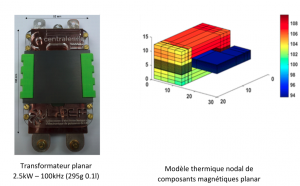

For slightly higher powers, « standard » planar magnetic components are a solution to increasing the power densities and the efficiency of on-board DC/DC converters. The EP team develops analytical and numerical models to predict the behaviour of planar transformers and inductors: HF behavioural models, loss models, leakage inductance, parasitic capacitances and thermal aspect. Prototypes can then be made using the planar ferrite core and foil windings or using the specifications of multilayer printed circuit boards (PCBs).

Magnetic components for EMC filters

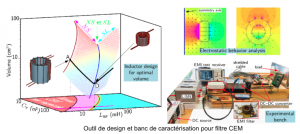

The team is developing characterisation methods and sizing tools in order to optimise the volume of filter elements for the electromagnetic interference generated by power converters. The frequencies considered can go up to several tens of megahertz, bringing into play various inductive and capacitive couplings between the various constituents of the system, participating in particular in the circulation of common mode currents in the earth conductor. Using characterisation methods developed in the laboratory, models are built with a broad frequency range of validity, taking into account the magnetic and electrostatic aspects, and the propagation in power cables.

These models can be used to work out the level of interference in the conversion chain. This is particularly useful in designing the smallest common mode coil needed to filter them.

2. Modelling and characterisation of active components, and design of HF conversion cells:

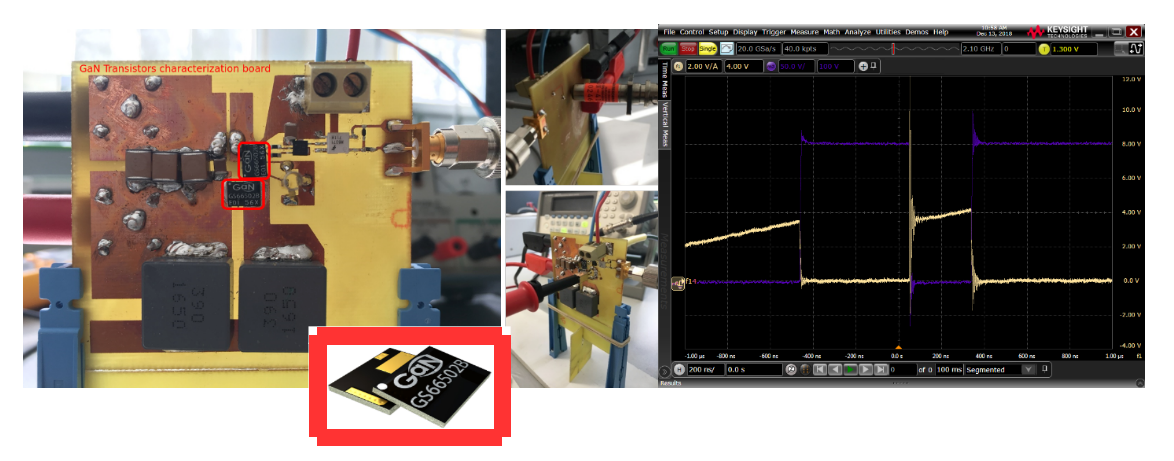

The size, weight and volume of the converters can be reduced by increasing the frequency of the converters. However, the switching cells become more sensitive to their operating environment. Fine simulations can be used to estimate the switching and the losses.

Using the silicon carbide (SiC) and gallium nitride (GaN) components currently available on the market means much higher switching frequencies can be attained compared with their silicon counterparts. As part of the CE2I project, L2EP has chosen to focus its efforts on GaN components. Models for fine simulation are developed, based on characterisations using innovative methods for power electronics. S parameters are used to accurately work out the intrinsic parasitic elements of the component (resistances, inductors, capacitors, etc.) The characterisation on PCB and the modelling of the latter are used to obtain a good agreement between the simulation and experimental data.

3. Conversion structures and applications

DC/DC converters for HVDC networks

The modelling and control of MMC type converters emerged from collaboration between the EP and Networks teams which led to the development of a simplified model of the MMC (DC/AC) converter, thereby facilitating the development of its remote control. This work is currently continuing for DC/DC type conversions for HVDC with structures based on the arms of the MMC: M2DC, double MMC, etc. The work is focused on the control modes, their degrees of freedom and the design to be adapted to the DC/DC transformation ratio. Implementations are planned on the MMC prototypes of the Networks team.

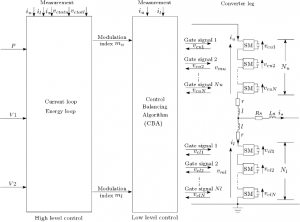

Control architecture of an M2DC arm – DCin = V1, DCout = V2

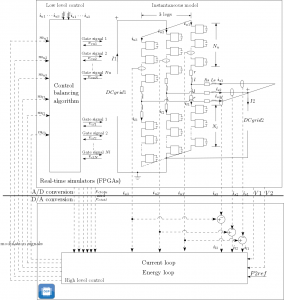

Control blocks for M2DC model – 3 arms MMC model (Networks team)

HF converters and hybrid storage for electric traction

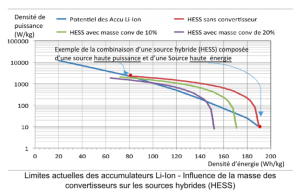

The development of low-carbon transport modes is forcing car manufacturers to develop high-performance, economical and sustainable sources of electrical energy. Despite the significant progress made on storage units, the development of electric vehicles on a massive scale isn’t possible. The hybridisation of energy sources (Power/Energy) can provide efficient solutions for certain applications. Following the work done by the EP team, relevant solutions were put forward in the area of the mass and volume of these sources, as well as the lifespan. Combining different energy sources must be done using converters to manage the energy flows.

These converters can be a handicap with regard to the volume and the on-board mass. Special care must therefore be paid to the size and mass of the latter. Work has already been done as part of a thesis on the subject with VALEO within the framework of the European SUPERLIB project (thesis by N. Allali). This will be followed by a second thesis from January 2019. As a result, various architectural solutions will be explored in order to reduce the power and the mass of the on-board power electronics.

Prototype of interface converter for hybrid storage systems (thesis by N. ALLALI -2016)