|

International Workshop - Summer School – HIL’16 |

|

This international workshop is focused on Hardware-In-the-Loop (HIL) simulation techniques for assessment of electrical subsystems before their insertion in a entire system. This workshop is aimed at Master and PhD students, engineers and scientists, from both academia and industry, who have to develop HIL simulation for test of electrical systems in various applications such as industrial multi-drive systems, traction and propulsion systems of hybrid and electric vehicles, power electronics and smart grids or renewable energy conversion systems.

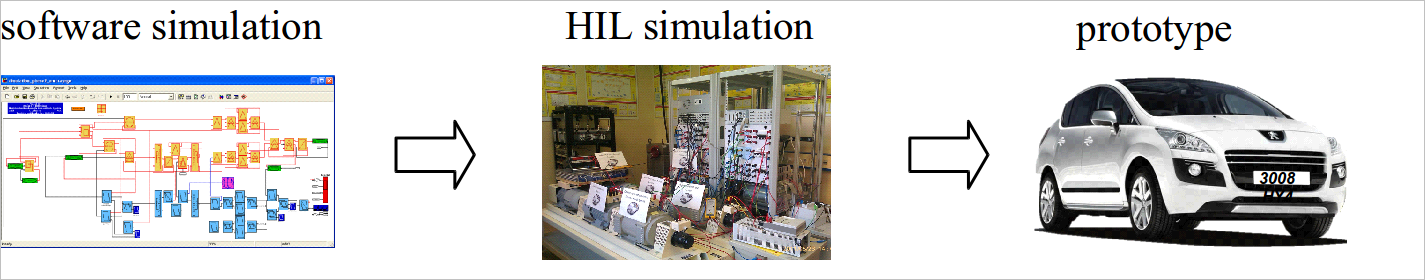

Hardware-In-the-Loop (HIL) simulation is used for validation tests of real-time embedded systems before implementation on actual processes [1]. Contrary to software simulation, HIL simulation uses one or several actual devices instead of their simulation models. The other parts of the process are simulated into a controller board or in parallel computers. Even though many HIL simulations are dedicated to assessing controller boards, drive validations are nowadays more and more developed using this methodology. HIL simulation thus enables us to check availability and reliability of electrical systems before their insertion into an entire system. Indeed, implementation constraints are taken into account, such as sensor accuracy, the sampling period, the modulation frequency, active limitations and so on. Moreover, fault operations can easily be tested in various cases. From another point of view, it could be valuable to insert a device, which is difficult to model (an internal combustion engine for example), in the loop. In this way, the influence of the model uncertainties could be tested using HIL simulation.

For many years, signal HIL simulation has been intensively used for controller assessment. The aerospace industry has used this technique, since flight control systems are critical in ensuring safety. This methodology yields exhaustive testing of a control system to prevent costly and damaging failures. Moreover, HIL simulations reduce development time and can enable more tests to be performed than on the actual system. From the 90s, many groups in the automotive industry have employed HIL simulation for testing embedded Electronic Control Units (ECU). Indeed, this methodology avoids intense and complex integration tests on the actual vehicle. Thus, the time development can be reduced and a high quality can be ensured. HIL simulation is becoming a standard for ECU development in the automotive industry

Power HIL simulation is currently being used more and more to develop new components and actuators in many fields. We can cite, for example, vehicle component evaluation, assessment of drive controls, power electronics and electric grid, servo control and robotics, railway traction systems, propulsions of electric and hybrid vehicle, education applications, etc.

General chair and co-chair

Example of the HIL simulation of an innovative traction system for Hybrid Electric Vehicle